|

The Hummer Transmission and Transfer Case

Edited by M Selig

OVERVIEW of COMPONENTS:

Hummers using the 6.2L engine (92-93) were mated to a GM TH400 (3L80) 3sp

automatic transmission, the heavy duty version of the ubiquitous TH350.

It has 3 forward gears and 1 reverse. It can be locked in 1st, 1-2,

or 1-2-3 (D). The ratios are 2.48, 1.48, and 1.00. Reverse is 2.08.

From 94 on, all Hummers use the GM 4L80E 4sp automatic. This is the

standard HD automatic trasmission in GM trucks. It can be locked into

1st, 1-2, 1-2-3 (D), or 1-2-3-4 (OD). The ratios are the same as the

TH400 except for a 0.75 overdrive. This trans comes in HD GM 3/4 and one-ton trucks.

Max input torque is 440 lbs-ft. The torque convertor is locking with

a ratio of 2.2:1.

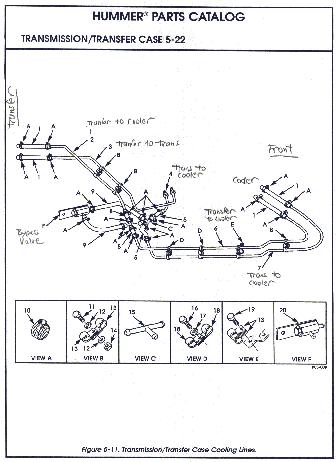

Transmission fluid driven by transmission pressure of aproximately 90- 120 psi, goes through

a cooler integrated with the engine oil cooler. From the cooler, the fluid goes though an

intercooler loop inside the transfer case, and then back to the transmission. There is a

bypass valve in circuit there to prevent the cooler fluid from all draining into the transmission

pan. The Dextran in the trans is separate from the Dextran in the transfer case with

separate drain plugs.

All Hummers use a New Process Gear (NPG) 242 2sp TRANSFER CASE. It is

a full time transfer case incorporating an open differential between

the front and rear driveshafts (DS). It has 4 modes, High (H), High

Locked (HL), Low (locked) (L), and Neutral (N). The ratios are

1:1 in high, 2.72:1 low. It is the same case that comes in HD 3/4-ton and 1-ton

GM's (except the dually which uses a Borg Warner case)

The input shaft and rear output shaft are co-linear. The front is a left-handed output,

chain driven.

In H, torque is evenly split front and rear. In HL, the differential is

locked (manual locker), forcing the front are rear driveshafts to turn

at the same rate. This is equivalent to a part-time 4wd system. The

L position forces the input shaft to turn a planetary gear assembly at

the front of the case. The ring gear is machined into the front case.

Low reduces the output shaft speed by 2.72:1. The differential is always

locked in low. The N position disconnects the input from the output shafts

totally. The differential is open in this position.

A sensor at the rear of the transfer case (TC) is used to determine

speed. Another sensor determines if the TC diff is locked or unlocked,

illuminating a status light.

The TC is cooled via transmission fluid flowing through an intercooler

inside the TC.

The engine, transmission, and transfer case are rigidly connected together.

The assembly is canted slightly to the right.

SERVICE:

Every 12 k miles the Trans and Transfer fluids (Dextran 3) needs to be changed.

This is Gerald's approach:

The first obstacle for me was to remove the intermediate shield of

the driveline protection. You have to remove 12 bolts and loosen

4 more. Then squish it falls on you!! Just kidding. The shield

is around 70 lbs or so I would guess. Things are always hard to

judge while blinking away dust lying on one's back. I loosened all

of the bolts in the back (it sits on the crossmember). Then, remove

the 8 bolting it to frame supports near the motor mounts. Then

remove the nuts from the front bolts but leave the bolts in.

I placed a jack near the center but further to the rear. Adjust jack

to support shield. Then pull the bolts from the front (you should be

at the front). You have the support the front. Lower the front slightly

and pull towards the front. The rears "fall off" the crossmember.

Lower the jack and roll it out.

Next, you need to remove the crossmember. Remove the nuts connecting

the transmission (rubber) mount to the xmember. Then, move the jack to

the rear and support the rear of the xmission. I used a section of

4x4 between the tcase and jack. You only have to touch it. Then remove

the huge nuts on the left and right bolting the xmember to the frame.

Curse and yell alot as you wiggle it free. I swear these things must

get longer after they are built because they are really stuck up in

there. Remove the rubber mount from the xmission to expose all the pan

bolts.

I am one of the lucky few who have a drainplug on my pan so I don't take

a bath with the stuff. Then remove the bolts except from one on the

left and right centers (loosen them of course). The tricky part is

that there is a bracket for the shift linkage that uses two of the pan

bolts. While supporting the pan, remove the final two bolts. The

exhaust crossover pipe prevents the pan from being lowered straight

down. You have to lower it, and then slide it back to clear the

exhaust. While doing this, you have to somehow get the pan lip out

from under the shift bracket. This is the most annoying part. You

just try different things until it comes out. You have to be very

careful to not hurt anything in the transmission. There are wires

right near the front that control the 1-2 shift solenoid that just

beg to be hurt. I was forewarned of this by a friend who watched

a mechanic do it (thanks Everett!!).

Pull down and twist left and right to work the pickup filter free. It will pop

out and start to shoot fluid down. Be sure to leave the pan under

the xmission to catch the stuff. There is a rubber or hard plastic

bushing (delrin?) that the filter plugs into. Just be sure it is in

good condition or else replace it. The filter should have come with a

new one if you need it (I did not). It is called a multi-lip seal.

Discard the filter. Insert a new one. Be sure to seat it fully. There

is a recess on the back that fits over the control valve. It is

pretty obvious.

Drain the pan. Clean and check the magnet stuck on the bottom of the

pan. It just peels off the bottom. There should not be any big

pieces or anything like that. You should just have the stuff that

looks like sludge. Your fluid should have come out pretty red and clear.

It should not be milky, bubbly, etc. Clean the gasket (just wipe it

will paper towels) and the mounting flange. Ditto for the flage on

the xmission too. Center up the filter and install pan. Reverse the rest.

I could not get my crossmember in. I had to grind the edges down just

a tad. I then got it in far enough to engage the nuts to the bolts

slightly. I then moved the jack to under the xmember and helped it the

rest of the way in. BTW, grinding the xmember does not seem too

uncommon. The dealer had to do it to me friends truck.

I measured how much fluid I took out so I put in the same amount (6 qt).

Check the dipstick to be sure you are in the ball park (like on the stick

someplace). Start engine, shift through gears, and check the stick.

Since the xmission is obviously cold, the level should be between the

two circles near the bottom (just a sanity check). Drive until hot,

and check at an idle.

You might as well change the transfer case fluid at the same time. There is no filter,

just a plug. However, you will need a pump to refill it. The fluid should be quite dirty

and brown looking (no filter).

Problems to be aware of:

The Transmission Vampire!!!!

The symptoms are tranny slipping or slow shifting coupled with low ATF

and/or ATF leakage on the ground. The absolute confirmation of an ATF

vampire is to open up the air cleaner housing. If there's ATF in the bottom

of the housing, you have been infected.

The cause is a leak in the transfer intercooler, such that the trans gets sucked dry. Fluid

floads the transfer and central ventilation system. Thanks Scott.

The Transfer Plug!!

The transfer case has a rubber plug in an unthreaded hole on the left side of the case about

halfway up. Both the hole and the plug are invisible behind the skid plate.

If the rubber plug comes out (which it does), you both loose lubricant and

unseal the transfer case. If you loose the plug and go fording water, you

will contaminate the lubricant and grenade your transfer case. One should check this

regularly.

4 to 2 speed Transmission!!!

On an occasion the trans will lose 2 of its 4 speeds. It is most likely at throttle switch.

Since the GM 4L80-E 4-speed trans is electrically controlled, rather than torque sensored, the

malfunctioned throttle switch screwed up the programing of the transmission. I couldn't

travel very far, so the dealer service suggested contacting a local GM dealer

and tell them what kind of GM transmission I have, and check to see if they

have a Tech-1 machine with a Mass Storage Cartridge. This machine can

test the transmission and tell exactly what was wrong. Anyway, to replace

the switch and reprogram the transmission, it cost me about $500, which I

didn't flinch at because I was so relieved that I didn't have to replace the

entire transmission. Thanks Dave.

SUGGESTED MODIFICATIONS:

TRANS TEMPERATURE GAUGE WITH REMOTE FILTER.

Off-roading and BTM are very hard on automatic transmissions. As the

the Hummer comes from the factory, we have no way to monitor the

transmission temperature. If you have drive line protection, it is

difficult to change the ATF.

I added a drain plug to the pan, a screw on filter in the line to the Hot side into the cooler,

and an ATF temperature gauge. Now, it is very easy to change ATF, draining the pan only

changes about l/2 of the ATF unless you drain the converter.

The pickup filter has approximately a l00-micron filtering capacity. The screw-on filters

have approximately a 20-micron rating. The pickup filter will stop any large debris, the

screw-on filter will remove smaller contaminents such as tarnish and debris. The pickup filter

should be left on. I checked the pickup filter on my Suburban at l50 k and it still looked

clean. I had changed fluid and screw-on filter every 25 k.

Therefore the remote filter will keep the ATF cleaner, you will not have to disassemble part

of the bottom of the wehicle to get to the pickup filter and during demanding conditions

you can watch the temperature, and if it gets too high, back off and let it cool down. If it

stays above normal, you can look for the problem.

The inline trans filter I used was from Summit Racing Equipment, Phone:

l-330-630-3030. You can buy it as a complete kit, #PRM l0677. It comes

with a temp gauge also.

For a drain plug, I am using a 1/2 in thread Rr20 NF magnetic plug via a bolt welded to the pan.

I am told the Hummer pan is thin gauge, cadnium coded. It is not optimal to braze, but to

mig weld, in case you are thinking of putting a drain plug in. The bolt-on plugs look a

little ringy dinky and can come loose easy but work.

I called Alan of PermaCool, Covina CA, 1-800-827-3768.

He told me that the inline filter will triple or double the mileage to

change the pickup filter (he is not alowed to tell me more than that). The

inline filter filters tarnished fluid which the stock filter does not. It

can keep the Dextron spanking clean as Charles made note.

|